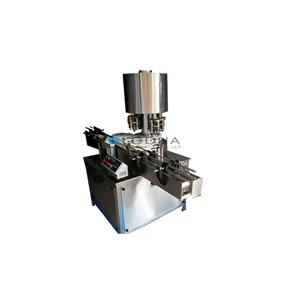

Automatic Single Head Bottle R. O. P. P. Capping Machine

Single Head Bottle ROPP Cap Sealing Machine Model: LI-BCS 1R is suitable for ROPP capping of Round Bottles with speed of maximum 35 to 40 Bottles per minute depending on Bottle Diameter, Height and Cap diameter.

Single Head Bottle ROPP Capping Machine is specially constructed in Stainless Steel finish including M.S. frame structure with Stainless Steel Cladding/Enclosures.

ROPP Bottle Cap Sealing Machine is equipped with Orientation type Cap Feeder for continues feeding of Cap for online operation on any liquid or powder filling line. Machine suitable for various sizes of Bottles as well as ROPP Cap with the help of change parts. ROPP Capping Machine is suitable for application in Pharmaceutical, Food, Pesticides, Chemical, Beverages, Liquor and other packaging industries having lower production requirement with automatic online operation.

The needs of ROPP capping machine in modern world is increasing by leaps and bounds. ROPP capping machine works with oval, square, oval, and even rectangular packaging or bottles without any hassle. Capping machinery takes on several different forms depending on the type of cap used and to what degree the automation is required.

Bottle ROPP capping machine is used to boost the production without any complexity. The other names of such machines include ROPP capper machine and ROPP cap sealing machine. They all are now used for low to medium to high production facility.

THE BENEFITS OF ROPP CAP SEALING MACHINES

Capping machines can offer a number of benefits to the manufacturers. Here we list a few –

SECURE, RELIABLE, AND CONSISTENT PRODUCTION

Automated capping process renders repeatable actions of capping machines. Bottle’s cap is required to be tightened with the same force and fashion, the automated bottle ROPP capping machine delivers the exact amount of pressure to maintain the uniformity. This way, ROPP capper machines offer secure, reliable, and consistent seals.

QUICK PRODUCTION

With ROPP cap sealing machines, the production can be fastening as automatic cappers can fix the bottles and/or containers very fast. At the end of the day, the production is increased and so is the profit. Semi-automatic or manual capping of the bottles require a lot of time as the workers need to check the seals and ensure the tightening process.

WIDE RANGE OF PRODUCTIVITY

Most ROPP capper machines that run automatically have great versatility. In other words, the machines would handle a big range of various tasks i.e. cap tires and sizes, provided the tightening rule is the same. For instance, spindle cappers are utilized to tight screws on caps; an automated spindle capper, nevertheless, can handle all types of caps such as flat and sports. It can even trigger the sprayer.

EASY OPERATIONS

It is easy to handle and operate bottle ROPP capping machines and the operators don’t need special knowledge about them. The operators simply need to resupply the caps in bulk timely.

CUSTOMIZED INTEGRATION

Lastly, almost all automatic ROPP cap sealing machines can be integrated with other systems or existing package processes. In a case where power conveyors are present, the machines may just get integrated themselves with the existing production line and once they are set up fully, they can start producing quality services. Tailoring or customizing such bottle ROPP capping machines is possible and that is the reason, more and more manufacturers are now adapting the latest capping systems.

Whether it is a part of a utterly automatic package process or a step towards the same, automated capping machines help increasing the efficiency and productivity of the whole capping processes.

SPECIAL FEATURES OF ROPP CAPPING MACHINE:

- No Bottle - No Capping System

- No Bottle - Machine Stop System

- Machine construction in Stainless Steel Finish

- Cap Feeder with Variable Speed System for feeding control of caps.

- Hopper can be completely dismantling for easy cleaning

- Various safety features including Clutch system to avoid Bottle Breakage or Jamming

- Single Drive synchronizing operation of Conveyor and Star Wheel

- Minimum Change over time